Engineering

Hydrogen IC FuelBox

Efficient. Compact. Transportable.

- Easy to transport for rapid deployment at the point of use

- Quick installation and commissioning as no high-pressure piping is needed

- Rapid refueling windows and large capacity for convincing proof of concept

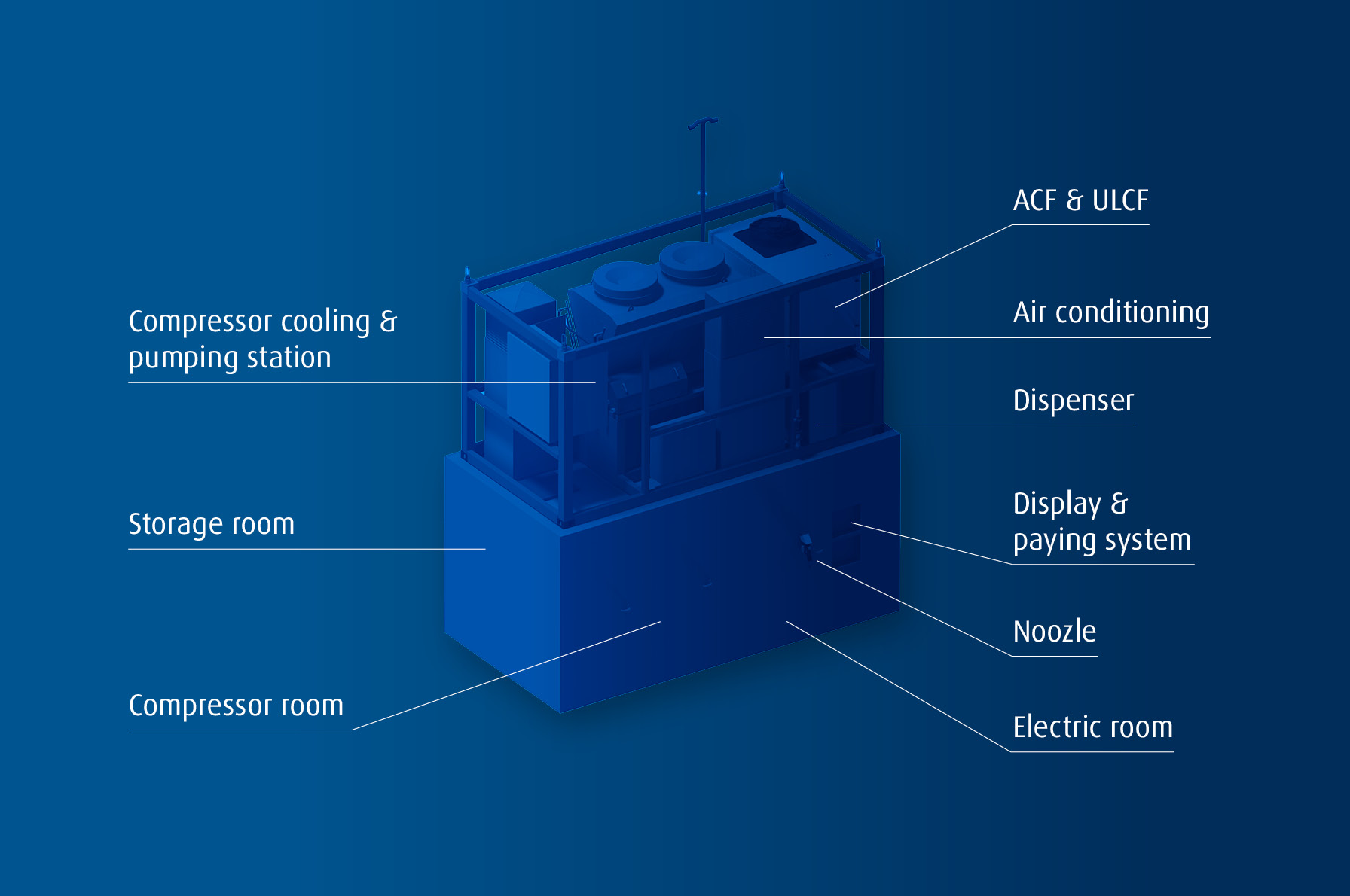

All-in-one transportable H2 refueling station

Growing adoption of hydrogen (H2) as a zero-emissions source of fuels driving the need for a broader, more flexible refueling infrastructure. Particularly as automotive original equipment manufacturers (OEM) and fleet managers contemplate extending fuel-cell drivetrains to new modes of transport, they would welcome a mobile, compact refueling concept that could be rapidly deployed to establish proof of concept.

Linde developed the IC FuelBox to meet this need. It is an all-in-one transportable hydrogen refueling station that integrates Linde’s proprietary IC 90/30 or IC 50/30 Ionic Compressors with an intermediate H2 storage tank and dispenser. With a small footprint of just 12 m², this ready-to-run unit can be deployed at just about any location – in record time with almost no installation effort.

Suited to multiple use cases

This unique station is suited to a wide variety of use cases. It gives fleet managers, for instance, a convenient, instantly available way to test new fleet concepts as it has the capacity to refuel up to 65 passenger vehicles or 10 heavy duty vehicles.

It also gives OEMs a solution to test fuel-cell buses, trains and all sorts of trucks with the capacity to serve up to ten heavy vehicles. In addition, it is the perfect fit for event managers of trade fair or exhibition grounds, providing a pop-up format to showcase the benefits of H2 fueling over a limited period of time.

Highlights of Linde´s transportable H2 station

→ Easy of transport for rapid deployment to the point of use

→ Quick installation, set-up and commissioning as no duct or high-pressure piping are needed

→ Minimal space requirements without compromising on capacity or ease of use

→ Rapid refueling windows and large capacity for convincing proof of concept

→ High-quality design in compliance with strict safety standards

Technical features

• IC90 or IC50 Ionic Compressor including auxiliary equipment

• Bank storage management

• 21 x 1000-bar or 21 x 550-bar cylinders à 50 liters and an option for an additional 550-bar 1.200 liter tube

• 350-bar or 700-bar dispenser

• H2 precooling unit

• Electric cabinet including AC, frequency converter and instrument air supply

• 115 kW connecting power

• Compliance with SAE J2601-2016

• Small footprint of 12m2

Register here to get more information on Linde’s IC FuelBox.

Hydrogen ready to run with Linde´s IC Fuelbox

The FuelBox based on Linde’s Ionic Compressor technology is a mobile fueling station for heavy-duty vehicles like trucks and for small demo and test fleets of buses.

IC FuelBox 50/30

The containerized system includes the required equipment for compressing, storing, cooling and refueling the hydrogen (H2) at 35 MPa at the container front.

→ Fueling demand: < 350 kg/day

→ Number of fuelings: 10/day

→ Fueling window: 24 hours

→ Parallel fueling: no

IC FuelBox 90/30

The containerized system includes the required equipment for compressing, storing, cooling and refueling the hydrogen (H2) at 70 MPa at the container front.

→ Fueling demand: < 350 kg/day

→ Number of fuelings: 65/day

→ Fueling window: 24 hours

→ Parallel fueling: no