Linde Engineering

The world is CHANGING.

And that means that we, as a world, must change our thinking. As global warming and climate change concerns intensify, we must intensify our efforts to reduce the concentration of greenhouse gases such as carbon dioxide (CO2) in our atmosphere. With Linde’s full breadth of carbon management technologies, we not only help with carbon emission reduction, we also help you explore all your options to store or potentially reuse captured carbon in other processes.

We MAKE SENSE of carbon management.

Carbon dioxide (CO2) is the world’s primary, human-produced greenhouse gas. From electricity and industrial sectors to transportation and buildings as emission sources, we must all do our part to mitigate climate change, protect human health and create economically sustainable operations—and that starts with robust carbon management.

The full value chain - from capturing CO2 before it’s emitted into the atmosphere to finding beneficial ways of reusing captured CO2 in industrial processes to a variety of other decarbonization solutions, has the ultimate goal to help industries find cost effective solutions in their transition to net-zero emissions of greenhouse gases like CO2. Because every industry is different, there is no one-size-fits-all approach. Effective carbon management takes an individualized approach to meet the unique business challenges and needs of each operation.

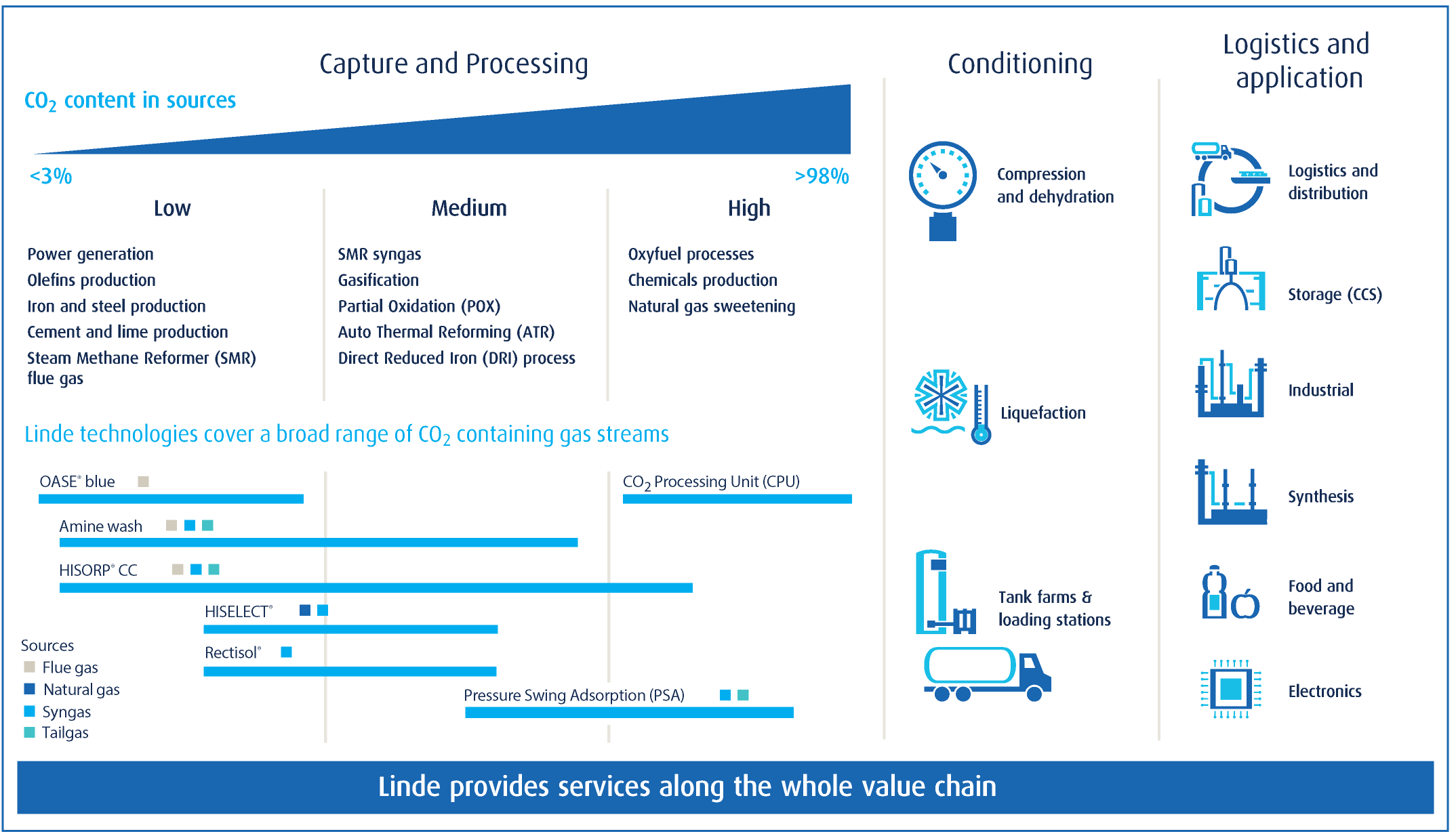

The carbon management VALUE CHAIN.

There are various different carbon capture technologies to choose from, depending on the CO2 concentration of the source gas stream:

-

Post-combustion capture, where the CO2 is scrubbed from low-CO2 concentration flue gases at ambient pressure, either by an amine wash process (OASE® blue) or an adsorption-based process (HISORP® CC)

-

Pre-combustion capture, where CO2 is captured from pressurized process gases with medium CO2 concentrations, either via an amine wash process, an adsorption-based process (HISORP® CC or PSA), a membrane process (HISELECT®) or a physisorption process (RECTISOL®).

-

Oxyfuel combustion, where CO2 is captured from high CO2 concentration flue gases of a pure oxygen-fired combustion process by means of a CO2 purification unit (CPU).

In addition to CO2 capture technologies, Linde offers CO2 conditioning solutions, such as liquefaction, dehydration and compression).

Once captured, the CO2 can follow various paths. One option is to put it to commercial use. From food- and beverage-grade CO2 to enhanced oil and gas recovery (EOR) to feedstock for the production of products like methanol or urea, the captured gas can be put to environmentally and economically beneficial use in other applications.

As an abatement measure, Linde can help you process and prepare your captured CO2 for in-ground sequestration. We handle the steps to ready your emissions for storage injection.

We CREATE technologies that manage emissions.

The first step to implementing the appropriate carbon management technology for your project is to holistically understand your unique business needs and existing plant setup. With over 140 years of experience and expertise in the process industry, Linde serves as a true partner, providing industry leading CO2 plant solutions that offer impactful, profitable and environmentally responsible ways of managing the carbon value chain. No matter which industry you are in, we engineer, build and support operation of the right carbon management solution for you.

We DESIGN carbon capture solutions.

Carbon capture, utilization and sequestration (CCUS) to reduce emissions of CO2 from point sources such as power plants, oil refineries, and industrial processes has become significantly important worldwide. Linde offers various solutions to effectively capture your CO2 emissions and significantly reduce your operation’s carbon footprint.

The three ways we capture carbon at the source are:

Post-combustion capture

This is the most widely used CCS technology for retrofitting industrial and power generating facilities. During the post-combustion process, flue gas resulting from burning fossil fuels passes through an absorber column with circulating liquid solvent, which absorbs the CO2 molecules. A heating medium like steam enables the adjacent regeneration column to release the CO2 from the solvent, and the CO2 is captured and piped away before it reaches the atmosphere.

Pre-combustion capture

Reforming and gasification processes react fossil fuels with air or pure oxygen to create a synthesis gas comprised of hydrogen (H2), carbon monoxide (CO), and carbon dioxide (CO2). The CO2 molecules are separated out of the syngas stream before combustion or further downstream chemical use of the syngas takes place.

Oxy-fuel combustion

Oxygen is separated from air and then combusted with a fossil fuel to produce CO2 and water vapor. This combustion, for example, drives turbines and generates electricity, then the water vapor is cooled, condensed, and removed while the CO2 is captured, purified and piped away.

We ENABLE CO2 purification, liquefaction and compression.

Complementing our carbon capture offering, Linde also specializes in on-site CO2 purification, liquefaction and compression technologies. From delivering standardized plants to designing and implementing customized plants, we handle everything from equipment supply to its installation, right up to all-inclusive turnkey solutions.

We PREPARE industries for a new world.

As environmental and climate mitigation pressures continue to rise, more and more companies are looking for flexible and cost-efficient solutions to improve their carbon footprint. At Linde, we work with companies in a variety of industries to cover the full carbon management lifecycle — extending from feasibility studies through engineering, procurement and construction.

Performance

Customization

Benefits

Performance

Designed to maximize cost efficiencies as well as reduce risk and increase production time through standardization and pre-testing, our range of standardized plants deliver the flexibility you need to adapt to variations in feed gas sources and product requirements—all within a compact footprint. What’s more, because Linde serves as both plant supplier and operator, we’re able to feed our operational experience back into future plant design, benefitting you with continuous improvements.

Customization

We also develop, engineer and construct customized plants to either meet more exacting application requirements or for capacity requirements in excess of 400 metric tons per day. Our customized plants are designed to give you the flexibility you require — including easily adjustable desired output levels, adaptability to all variations of feed gas sources and remote capabilities for start-up and shut down within a matter of hours.

Benefits

With an on-site carbon management solution from Linde, you not only contribute to climate and environmental protection, but you also benefit from:

- Minimized operating costs with energy efficient designs and automated operations

- Maximized uptime and ease of maintenance with high quality components, spare part delivery and after sales support

- Advanced flexibility with easily adjustable output levels, plant designs adaptable to all variations in feed gas sources and quick start up/shut down capabilities within a matter of hours

- Options for remote operations that increase manageability through an optional dedicated port for quick plant start-up/shut down capabilities, fully automated product analysis and truck loading and weighing

- Unparalleled expertise

Our clean technology portfolio has helped reduce or manage harmful emissions from a number of industries, such as:

Energy and Utilities

Electricity production generates the second largest share of greenhouse gas emissions. Approximately 62 percent of electricity in the US comes from burning fossil fuels, mostly coal and natural gas.

Cement

With the demand for new buildings and infrastructure projected to increase considerably in the next decade alone, the cement industry, at seven percent of global industrial CO2 output, has to take dramatic action to reduce their carbon footprint

Refining

By integrating CCUS with other practices such as energy efficiency, using low-carbon oil, and tapping into renewable power generation, refineries can lower CO2 emissions practically and sustainably.

Iron and Steel

The amount of CO2 emissions from iron and steel manufacturing is almost double the amount of iron and steel created: 1.85 tons of carbon per 1 ton of steel. If steel were a nation, it would be the 5th largest producer of carbon emissions in the world.

What is Carbon Management?

Carbon dioxide is a global environmental challenge. What is your path to net zero emissions?

Watch the videoCO2 Capture in Industries

Integrating carbon management into your processes future-proofs your business. What technologies are the best fit for your operations?

Watch the videoPreparing CO2 for Sequestration and Storage

CO2 sequestration and storage underground is a crucial means to meeting global warming mitigation targets. Linde has the technologies and expertise to capture, process and compress CO2 in preparation for storage.

Watch the videoWhat is Carbon Management? (In depth)

Carbon dioxide (CO2 ) is the world’s primary, human-produced greenhouse gas. Carbon management has the ultimate goal to help industries find cost-effective solutions in their transition to net-zero emissions of greenhouse gases like CO2. Because every industry is different, there is no one-size-fits-all approach. Effective carbon management takes an individualized approach to meet the unique business challenges and needs of each operation.

Watch the videoWhat is Carbon Capture?

The main carbon capture (CC) technologies in use today are post-combustion CO2 capture, pre-combustion CO2 capture, and oxyfuel combustion. Linde experts explain these and discuss examples where each technology can be applied.

Watch the videoGetting Started With Carbon Mangement

Effective carbon management takes an individualized approach to meet the unique business challenges and needs of each operation. How can you start assessing your emission points, and what are your options for reducing CO2 emissions?

Watch the videoGet our Carbon Management guide to help you navigate the path to Net Zero!

To help illustrate the effects of CO2 emissions and what can be done to curb them, we have developed a comprehensive guide that contains both necessary context and solutions – everything you need to help forge an effective path toward your clean energy goals.

Download the eBook

Let us help manage your CO2 emissions

We collaborate as a partner. We innovate through expertise. We deliver through experience. Let’s talk.